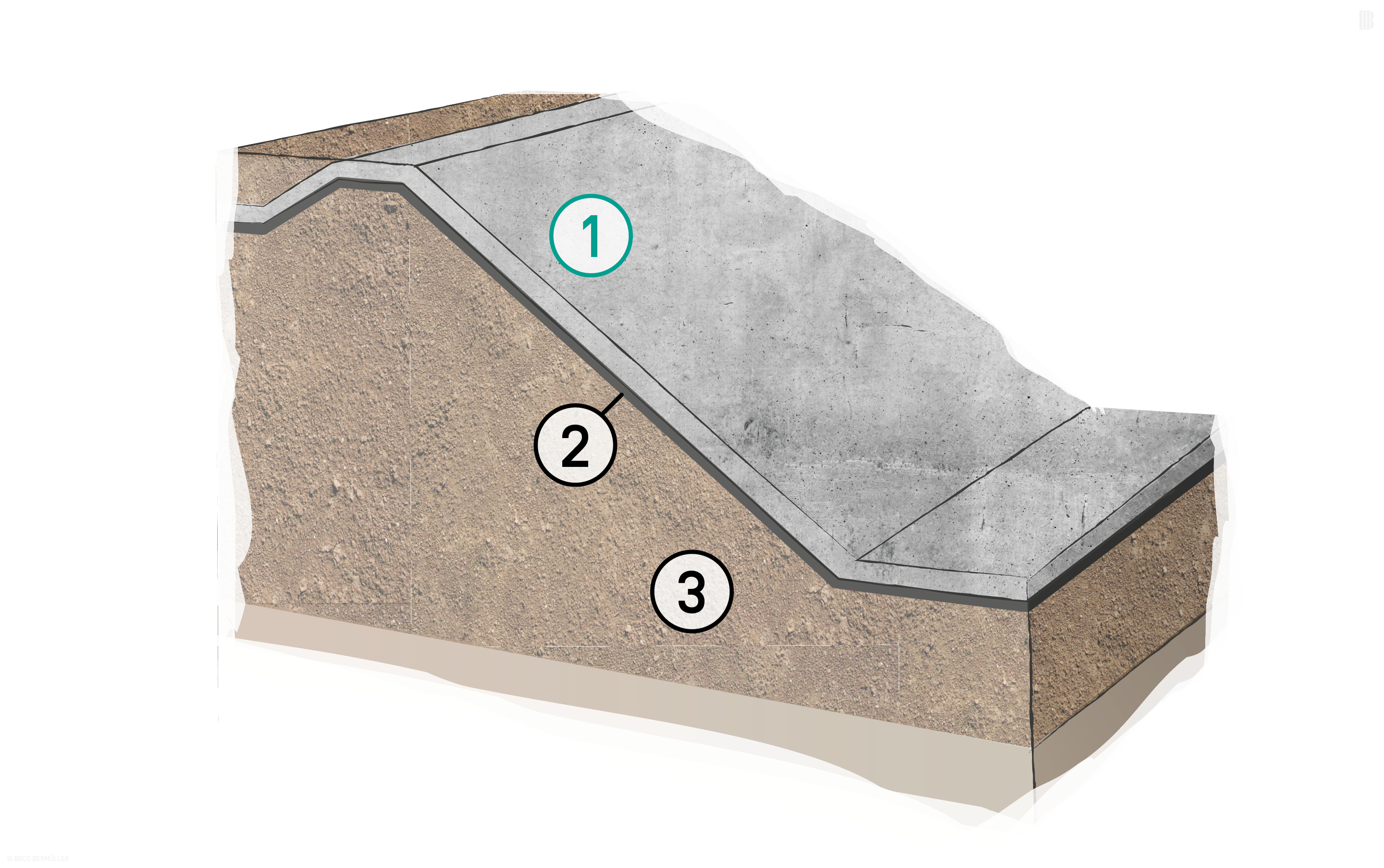

The flexible CONCRETE CANVAS composite mats comprise a multi-layer combination of geosynthetics with a specially developed dry concrete mix.

The innovative material has a water-permeable top layer made of UV-resistant polyester geotextile and a geotextile support layer with an additional coating. A dry concrete mix with a clearly defined density is placed between these two layers using a special production process. After setting, the fine fibres strengthen the concrete inside, reduce crack propagation in the long term and increase the fracture stability of the concrete layer. The concrete composite thus combines the advantages of geosynthetics with the robust properties of concrete.