BETEX NW Non-woven Fabrics

Non-woven fabrics belong to a group of construction materials that perform important functions in earthworks, road construction and civil engineering. The various special functions, such as separating different types of soil and filtering soils that need to be drained, make it necessary to differentiate between the non-woven fabrics in order to select the right one.

It is often possible to simply choose the correct fabric according to the geotextile robustness classes (GRK) as defined in the “Merkblatt über die Anwendung von Geokunststoffen im Erdbau des Straßenbaues M Geok E” (Leaflet on the use of geosynthetics in earthworks for highway construction). In other cases, the fabric must be chosen according to the site conditions.

The M Geok E is used to determine the suitability of the nonwoven.

Your advantages

Good mechanical and hydraulic filtration properties

Weatherproof

Good adaptability

Easy to install

General

BETEX NW Non-woven Fabrics are manufactured from high-quality polypropylene spin fibres in one of the most modern production plants in Europe.

This polymer has high chemical resistance, even to aggressive media such as those with a high pH value. In contrast to conventional, purely mechanically bonded products, BETEX NW Non-woven Fabrics are also thermally treated, in a second production stage.

Thanks to this second-phase treatment, the advantages of mechanically bonded non-woven fabrics, such as flexibility and effective filtering, are combined with the robustness and tensile strength of thermally bonded products.

BETEX NW Non-woven Fabrics have a small characteristic mesh size and high water-permeability and thus meet the requirements of even the most demanding types of application.

Non-woven fabrics are assigned to geotextile robustness classes 3 to 5. Their use is specified in the “Merkblatt über die Anwendung von Geokunststoffen im Erdbau des Straßenbaues M Geok E” (Leaflet on the use of geosynthetics in earthworks for highway construction), which ensures correct selection and handling by everyone involved in the construction process.

Functions

Separation

BETEX NW Non-woven Fabrics separate different types of soil. During installation and when the completed structure is in use, they prevent the different materials from becoming mixed as a result of external mechanical or hydraulic loading. This separation allows each different soil layer to maintain its specific properties.

Filtration

The filtration effect of a non-woven fabric becomes more important when, in addition to separation, it also has to contend with the effects of water. In such cases, the structure relies on both the separation and filtration functions of the fabric.

When constructing traffic routes or drainage systems in soils that present a filtration problem (such as silty sands), a suitable filter must be used that can keep the soil in place and drain away pore water without any significant raising of the seepage line.

The right combination of mechanical and hydraulic filtration has been achieved if the soil is held securely in place and water can easily drain away.

Thanks to their thermofixed surface, the mechanically bonded BETEX NW Non-woven Fabric has an adequately dimensioned characteristic opening size and good water permeability.

Technical details

Special guidelines are available for the different applications of non-woven filtration fabrics and these should be consulted when selecting products. Guidelines for the use of non-woven fabrics in road construction are contained in the “Merkblatt über die Anwendung von Geokunststoffen im Erdbau des Straßenbaues M Geok E” (Leaflet on the use of geosynthetics in earthworks for highway construction). Reference to these guidelines is also made in the recommendations of “Geotechnik der Deponien und Altlasten” (Geotechnical Aspects of Landfill and Brownfield Sites) published by the DGGT (German Society for Geotechnical Engineering).

In order to ensure that non-woven fabrics continue to perform their intended function within the structure after installation, geosynthetics are assigned to geotextile robustness classes (GRK) in accordance with M Geok E (Leaflet on the use of geosynthetics in earthworks for highway construction). The geotextile robustness classes take into account the installation method and the type of fill material used.

Important parameters for the allocation to GRK classes include the soil class and grain shape of the soil to be filtered, the load applied by the fill material, and also the stresses encountered during the installation and construction works. The type and method of installation and compaction of the fill material are just as relevant as the expected loading by construction traffic.

The various non-woven fabrics in the BETEX NW range, with their different mass per unit area values and corresponding static puncture resistance values, cover all GRK classes.

Non-woven fabrics are assigned to geotextile robustness classes 3 to 5. Their use is specified in the “Merkblatt über die Anwendung von Geokunststoffen im Erdbau des Straßenbaues M Geok E” (Leaflet on the use of geosynthetics in earthworks for highway construction), which ensures correct selection and handling by everyone involved in the construction process.

Applications

BETEX NW Non-woven Fabrics are used in situations where seepage water from soils with fine or mixed-size grains needs to be drained from poorly draining soils into a drainage system. The fabric separating the soil layers has the task of preventing fine grains from entering and clogging the drainage system and causing it to fail.

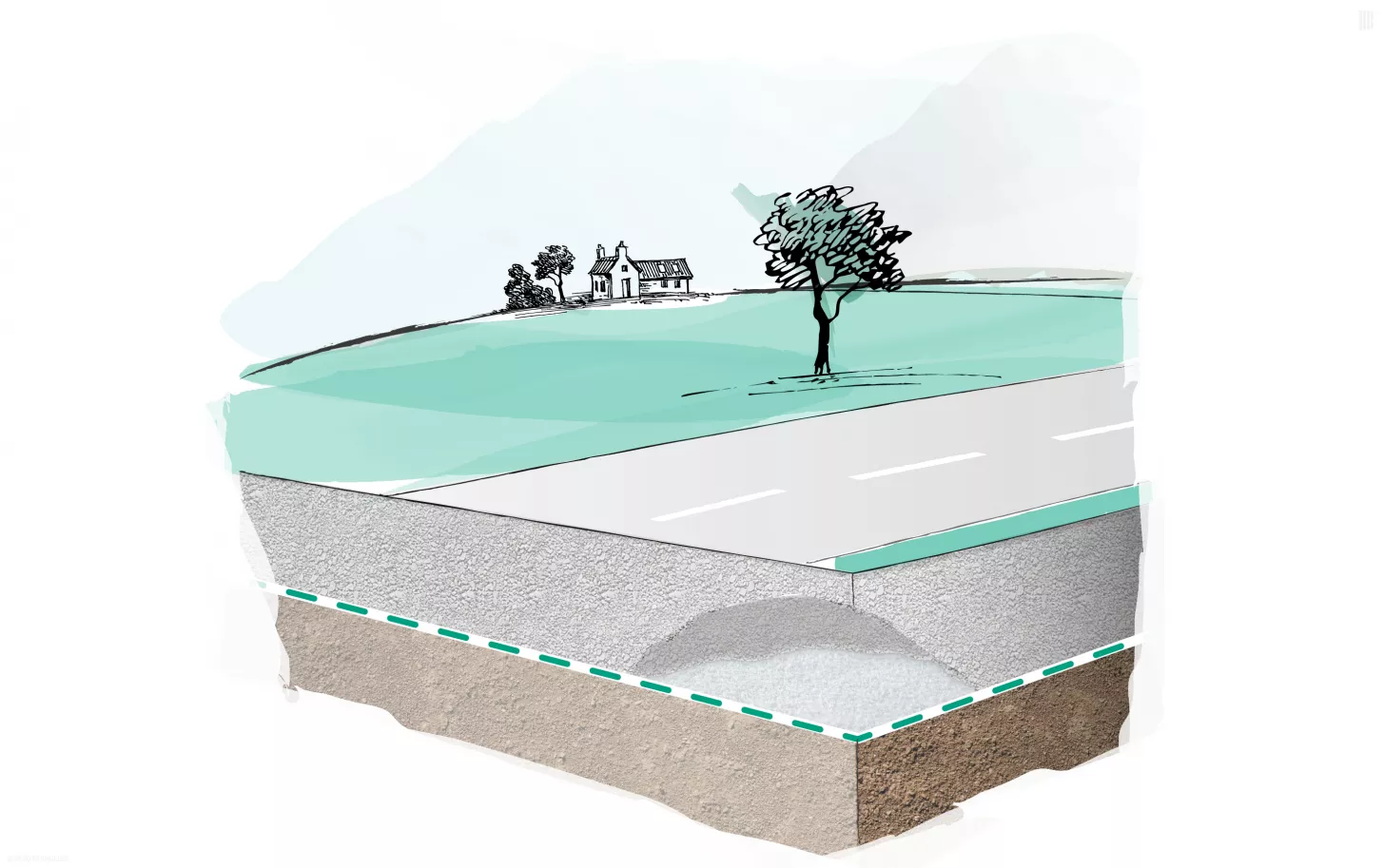

Separation layer under a dam

- Bound upper construction layers

- Unbound upper construction layers

- Base layer

- BETEX NW Non-woven Fabric

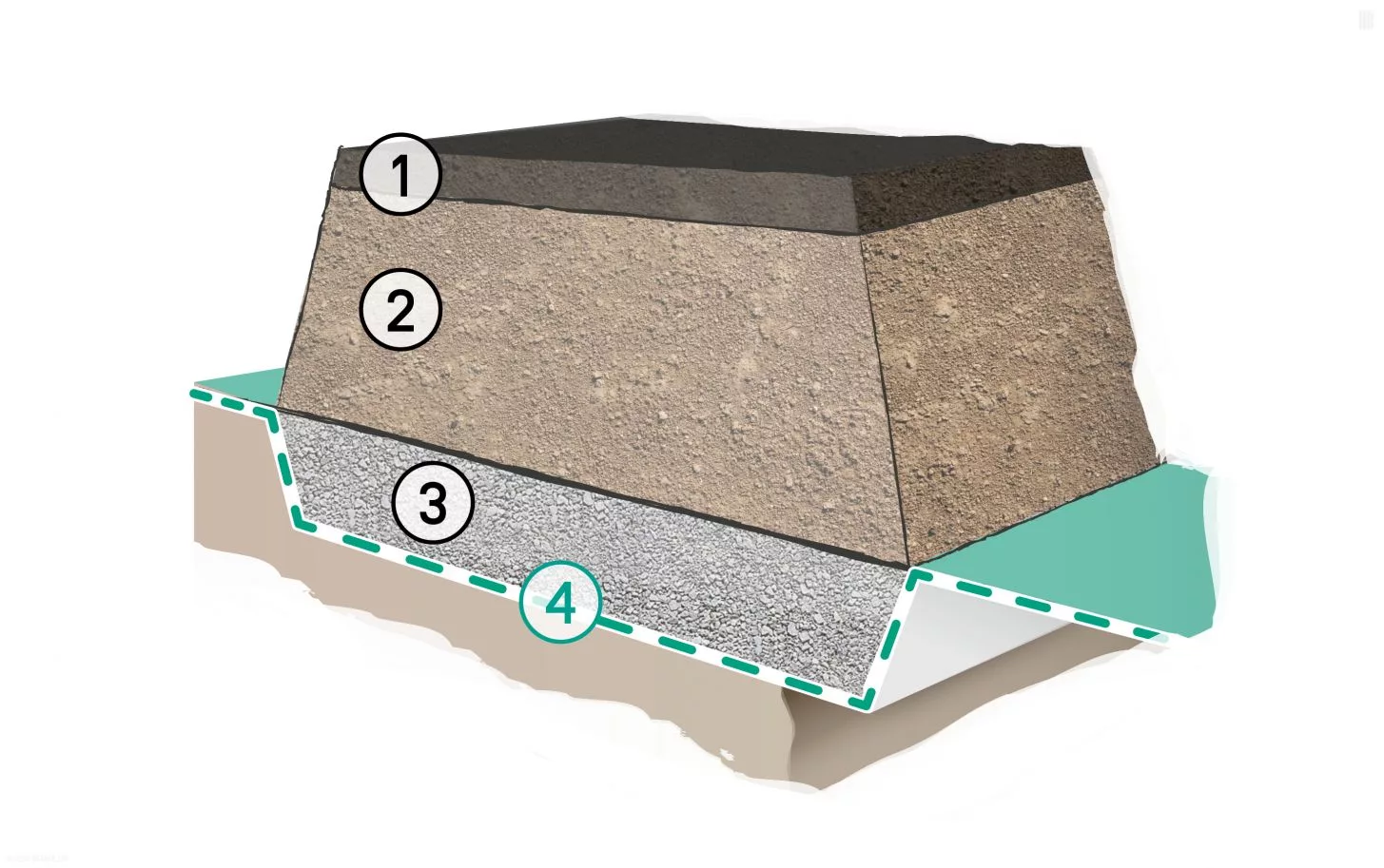

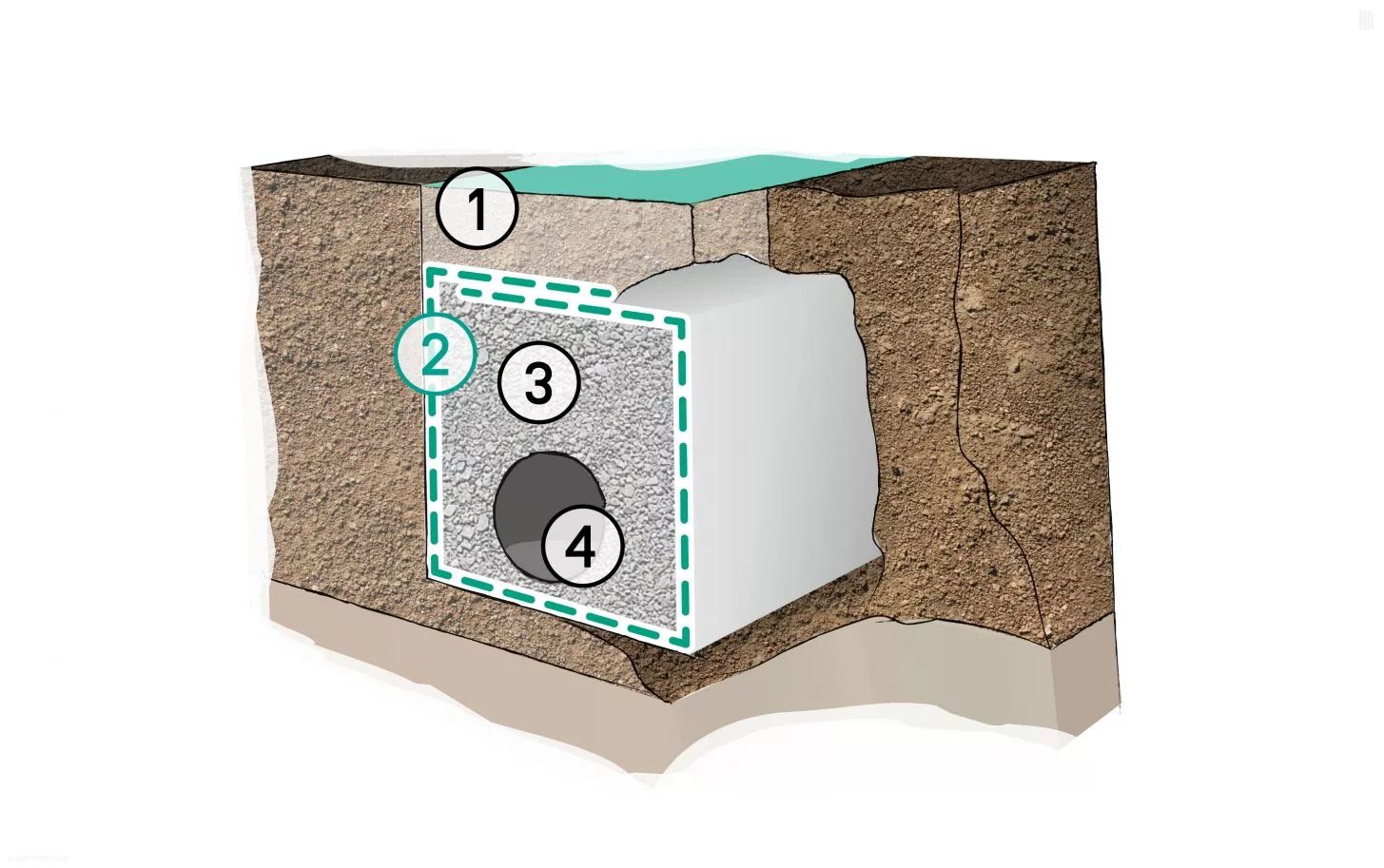

Separation layer in the case of partial soil replacement

- Bound upper construction layers

- Unbound upper construction layers

- Soil replacement

- BETEX NW Non-woven Fabric

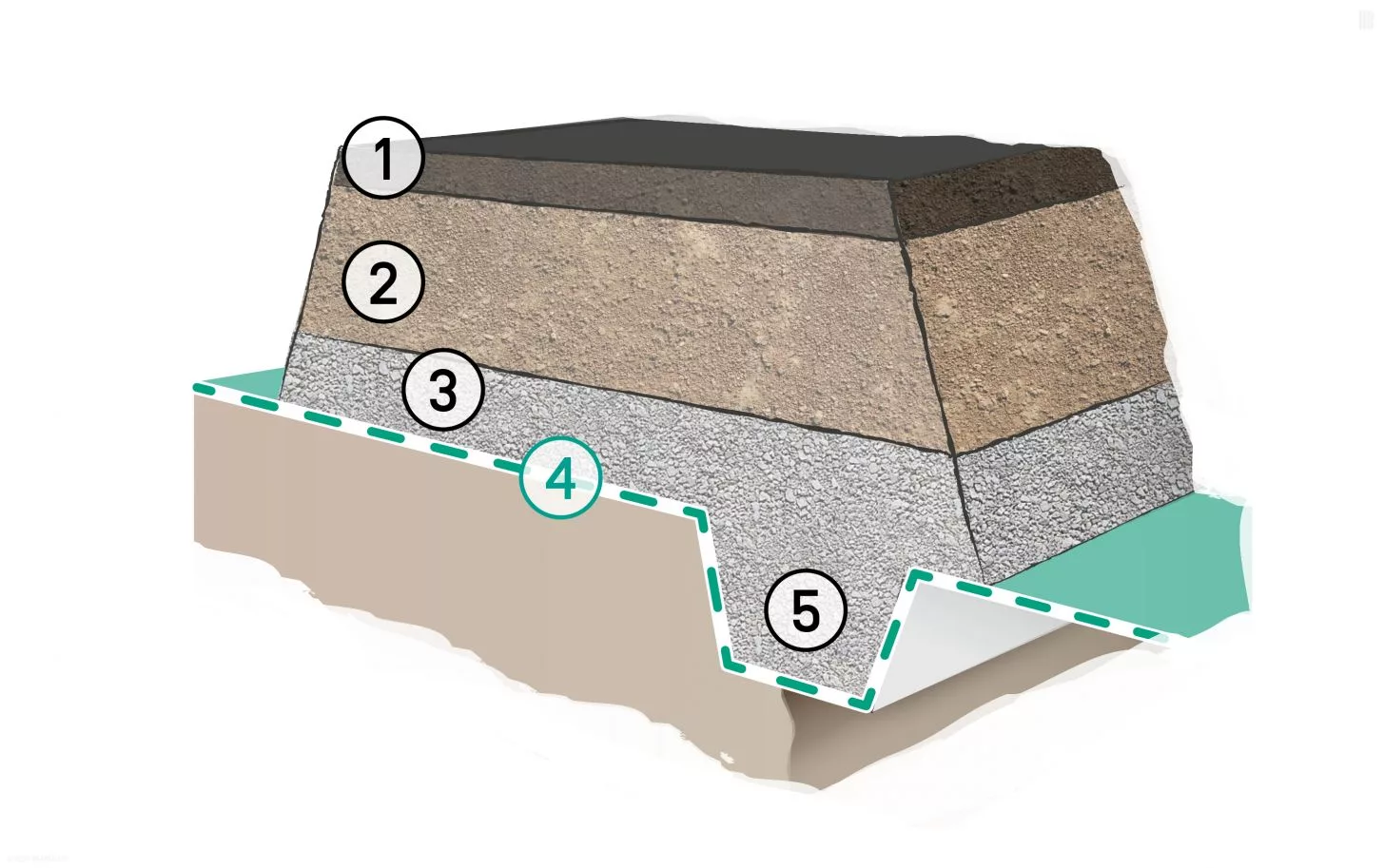

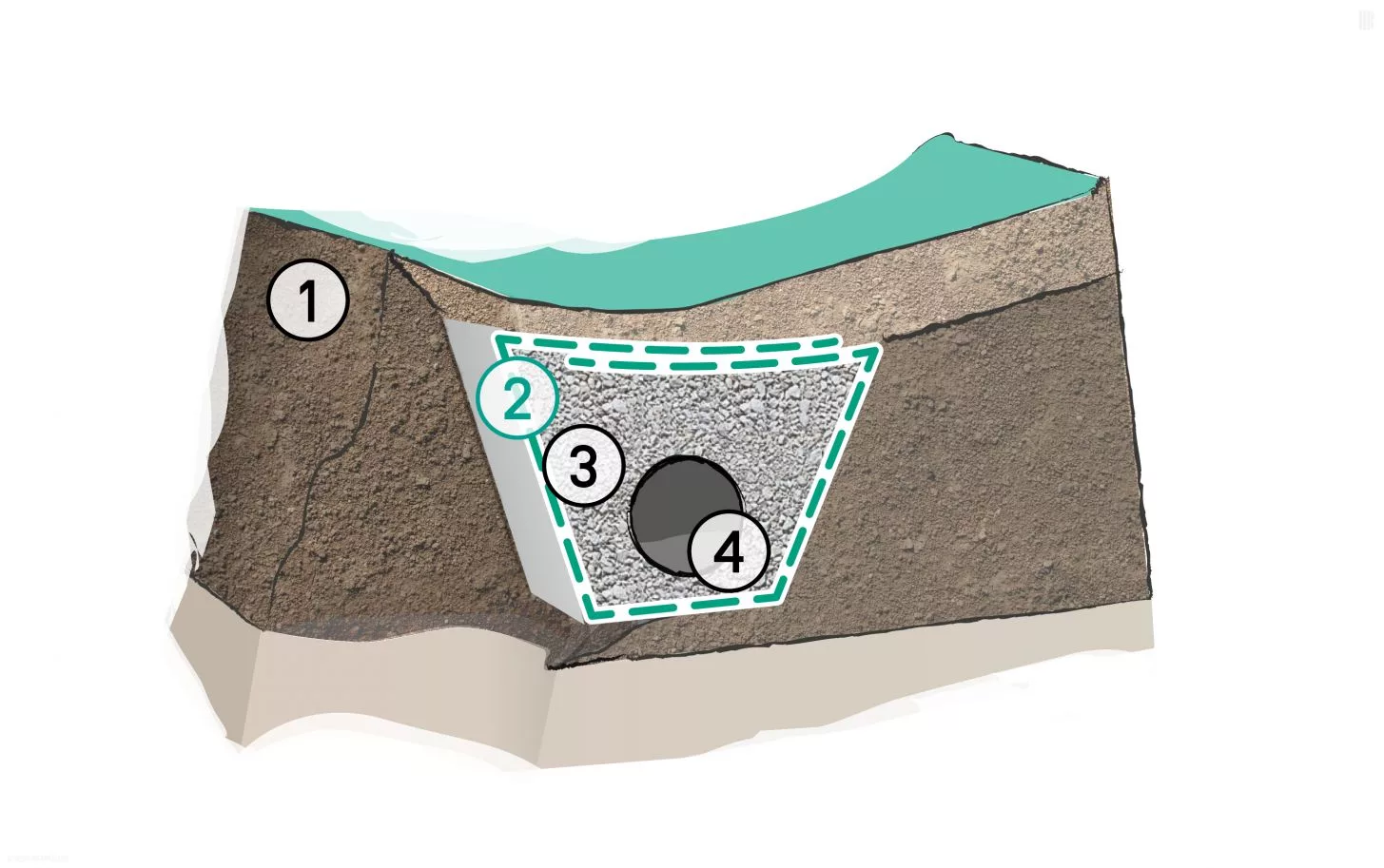

Separation layer for infilling and covering ditches and channels

- Bound upper construction layers

- Unbound upper construction layers

- Partial soil replacement

- BETEX NW Non-woven Fabric

- Ditch/channel

Separation layer under bound and unbound traffic routes

- Unbound upper construction layers

- BETEX NW Non-woven Fabric

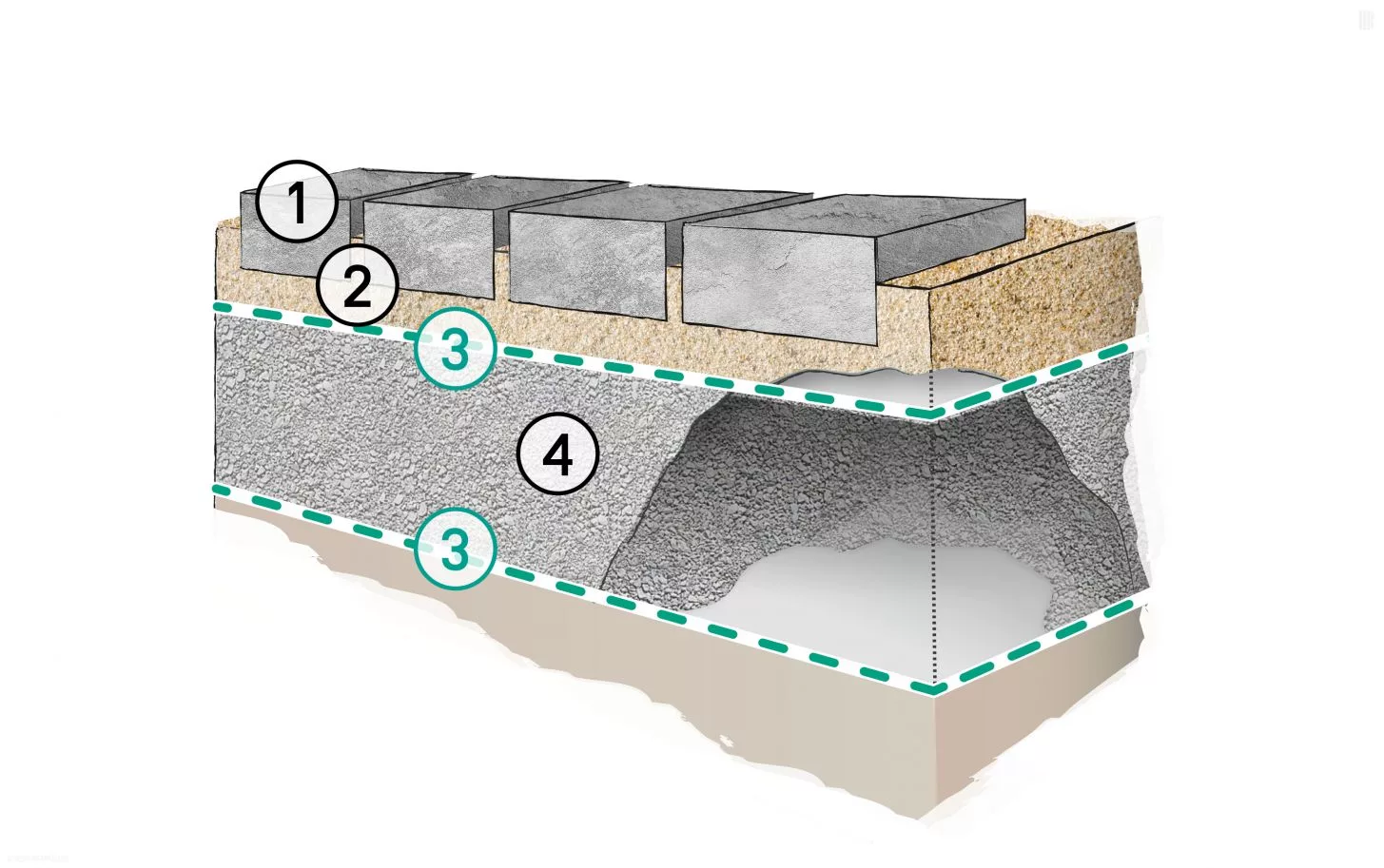

Separation and filtration in traffic infrastructure

- Block paving

- Bedding for paving

- BETEX NW Non-woven Fabric

- Base course

French drain

- Backfill material

- BETEX NW Non-woven Fabric

- Free-draining fill material

- Partially perforated pipe

Trench backfill

- In-situ soil

- BETEX NW Non-woven Fabric

- Free-draining fill material

- Partially perforated pipe

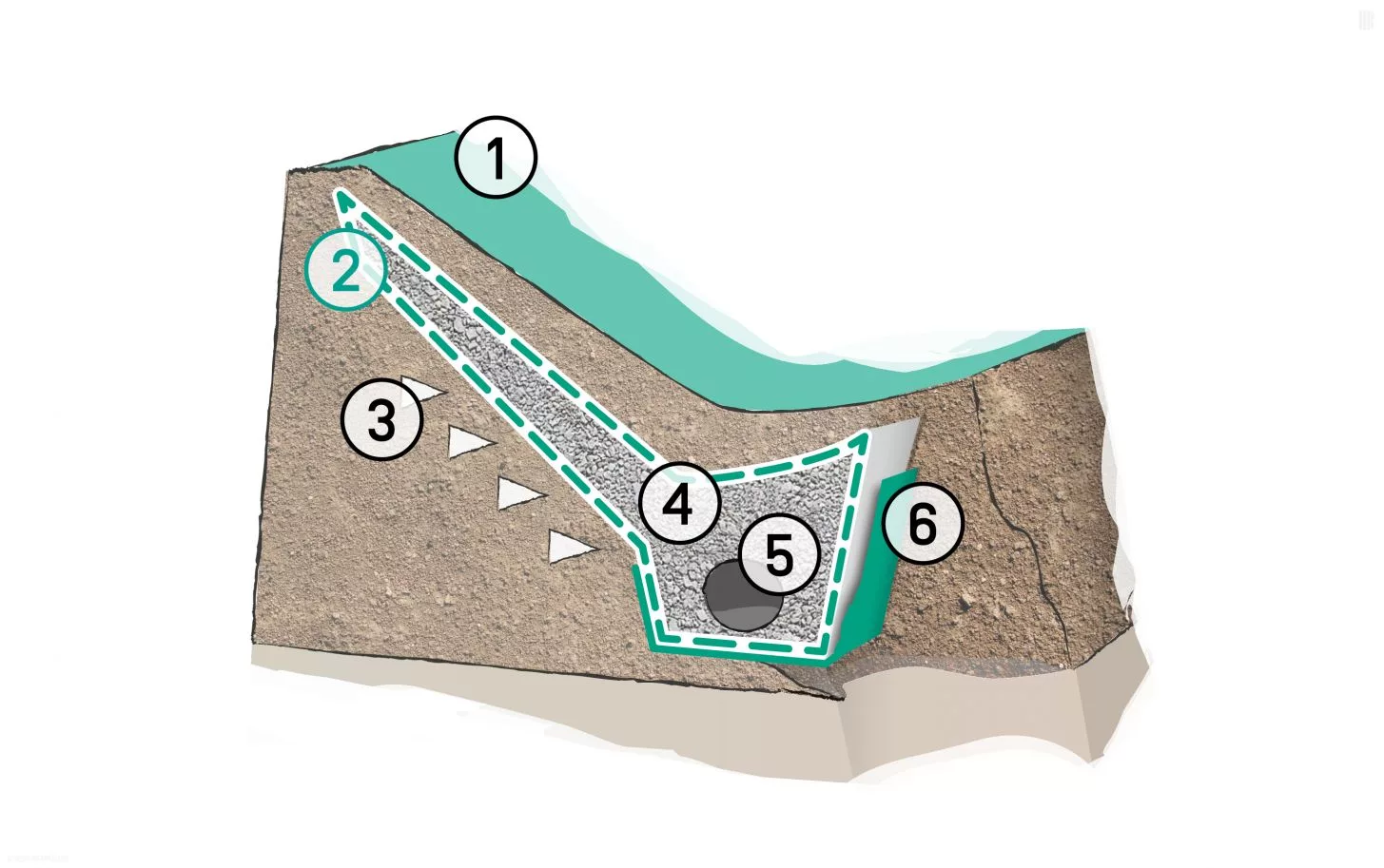

Drainage layer for slopes (perforated pipe)

- Topsoil

- BETEX NW Non-woven Fabric

- Seepage water

- Free-draining fill material

- Partially perforated pipe

- Sealing membrane, if required

Separation and filtration layer for drainage systems

- Soil and vegetation

- BETEX NW Non-woven Fabric

- Sealing membrane

- Free-draining fill material

- Partially perforated pipe

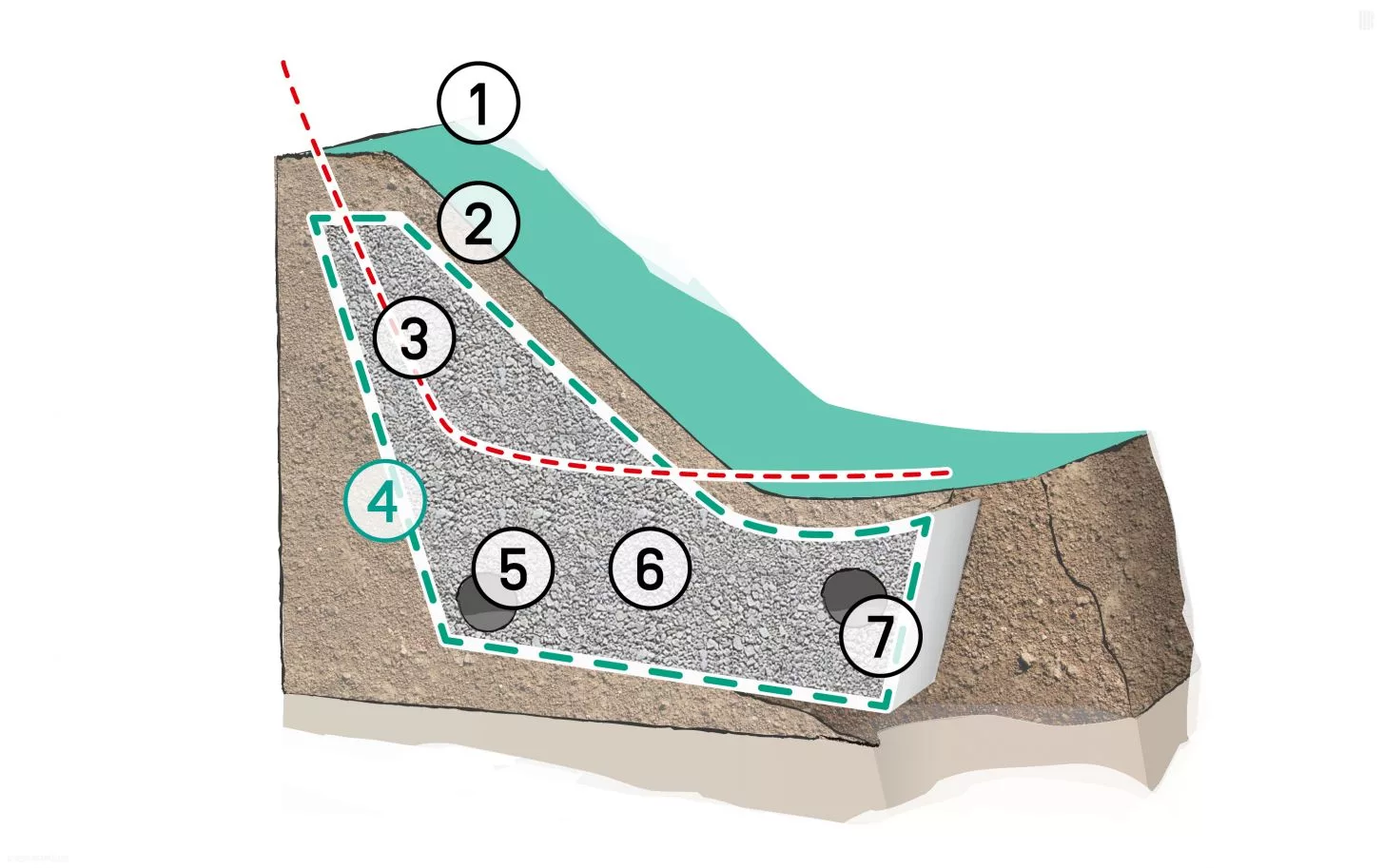

Reinstatement of a slipped embankment by installing a perforated pipe

- Soil and vegetation

- Standard inclination 1 : 1.5

- Plane of previous slip

- BETEX NW Non-woven Fabric

- Partially perforated pipe

- Free-draining fill material

- Drainage or longitudinal road drainage

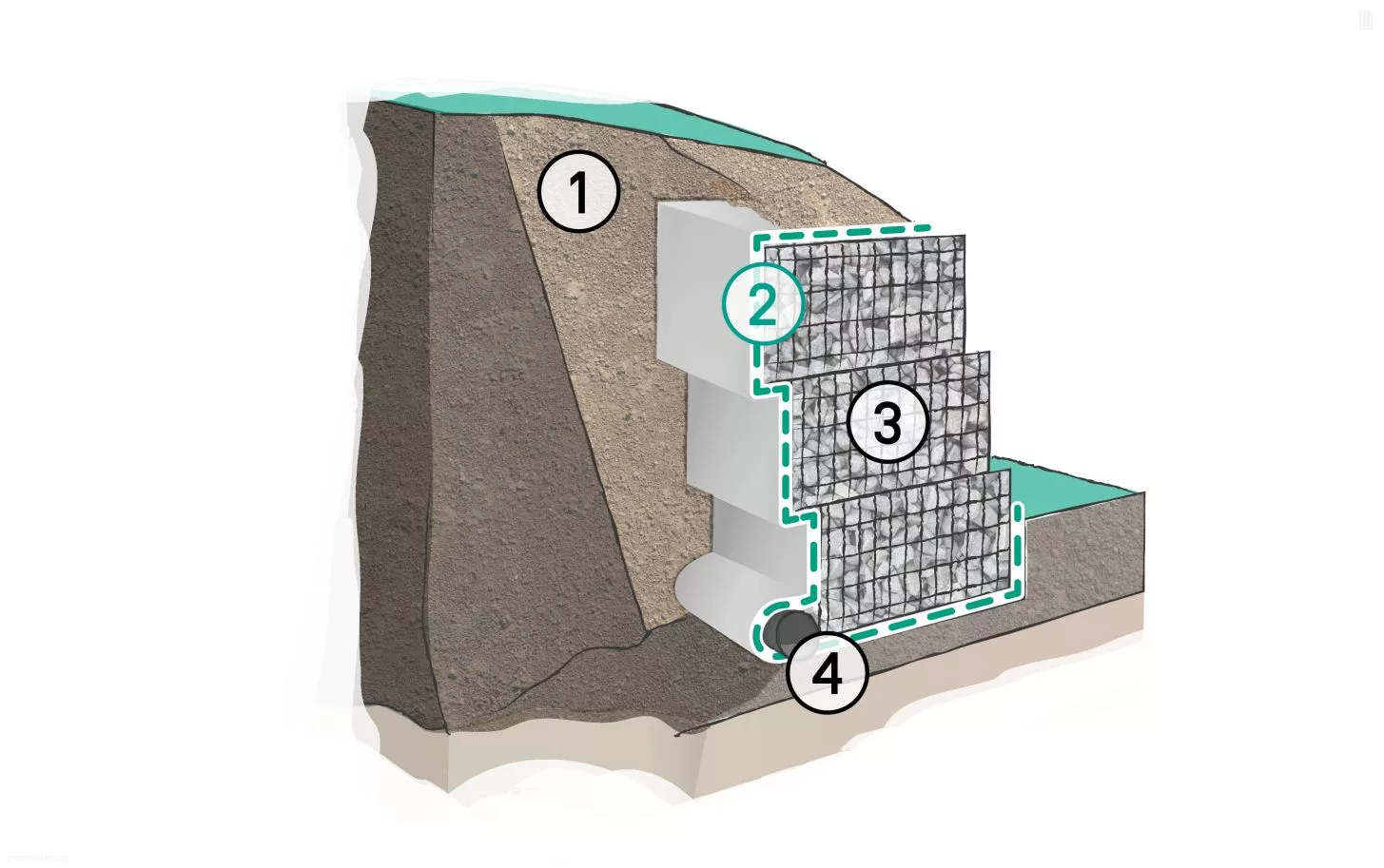

Filter layer behind gabions

- Backfill material

- BETEX NW Non-woven Fabric

- Gabions

- Drainage pipe

Data

| Properties | NW 9 | NW 10 | NW 13 | NW 16 | NW 21 | NW 26 |

|---|---|---|---|---|---|---|

| Product type | Mechanical bonded and thermally treated nonwoven | |||||

| Raw material | Polypropylen (PP) white | |||||

| GRK | without | without | 3 | 3 | 4 | 5 |

| Areas of application | ||||||

| Roof greening | ● | ● | ● | ● | ● | ● |

| Drainage system | ○ | ○ | ● | ● | ||

| Railway construction (with approval) | ● | ● | ● | ● | ||

| Green areas | ● | ● | ● | ● | ● | ● |

| Road and traffic area | ● | ● | ● | ● | ||

| Underground car park greening | ● | ● | ● | ● | ● | ● |

| Road construction | ● | ● | ● | ● | ||

Installation

- The subsoil should be as flat and even as possible in order to ensure full contact with the fabric across its entire surface.

- The fabric must be laid flat and free of creases. Creases resulting from the shape of the structure should be removed by cutting the fabric and allowing it to overlap.

- Then follows the installation of the fill material, on the basis of which the corresponding non-woven fabric was selected according to the GRK class. The covering of the non-woven fabric with soil can be easily slotted into the construction schedule within a two-week period.

- When filling and compacting material on top of the fabric, care must be taken to prevent displacement or creasing of the fabric.

Our detailed installation and laying instructions for BETEX NW Non-woven Fabrics must also be followed.

Advantages

- Good mechanical and hydraulic filtration properties

- Excellent chemical resistance

- Good weather resistance

- Robust, to cope with installation conditions on site

- Malleable and easy to lay

- Easy to cut to size using a cutter or Stanley knife

Gallery

Further information about:

BETEX NW Non-woven Fabrics

BETEX NW Non-woven Fabrics

BETEX NW Non-woven Fabrics

Product Brochure

Further applications