BEFORCE Woven Fabrics

A common problem encountered in the construction of traffic routes is the inadequate load-bearing capacity of the subgrade. In order to permanently increase the load-bearing capacity, either the loads must be transferred to sufficiently load-bearing layers at a deeper level (deep foundations) or suitable measures must be taken to improve the existing subgrade.

Traditional soil stabilisation methods such as soil replacement or soil treatment using lime are very laborious and costly and are not always possible. This is where BEFORCE Woven Geotextiles offer a simple and cost-effective solution for improving the load-bearing capacity of bound or unbound foundation layers.

Your advantages

Separation of bearing course material from substrate

Reinforcing effect in the foundation course; increases the load-bearing capacity; reduces deformation and ruts

Easy to install, low labour input

Cost savings due to reduction in thickness of unbound base course

General

BEFORCE Woven Geotextiles offer a simple and cost-effective solution for improving the load-bearing capacity of unbound upper or foundation layers.

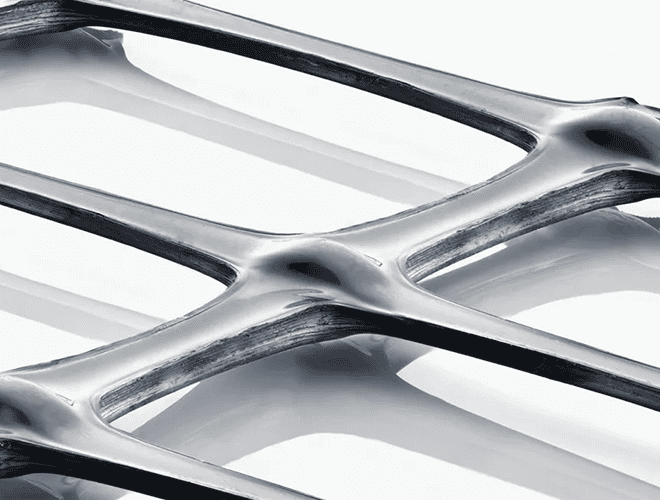

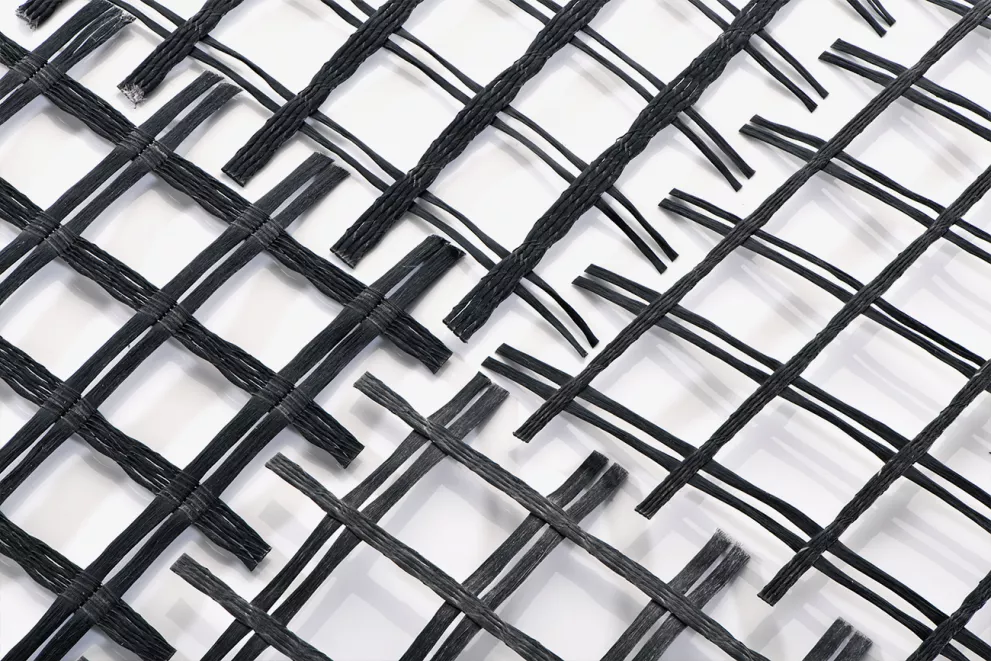

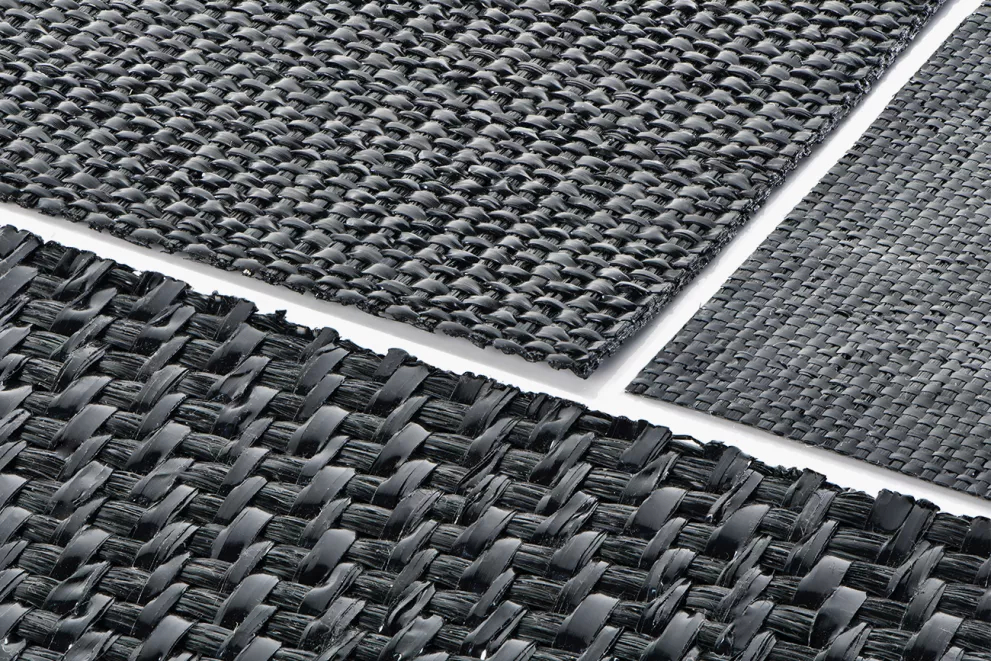

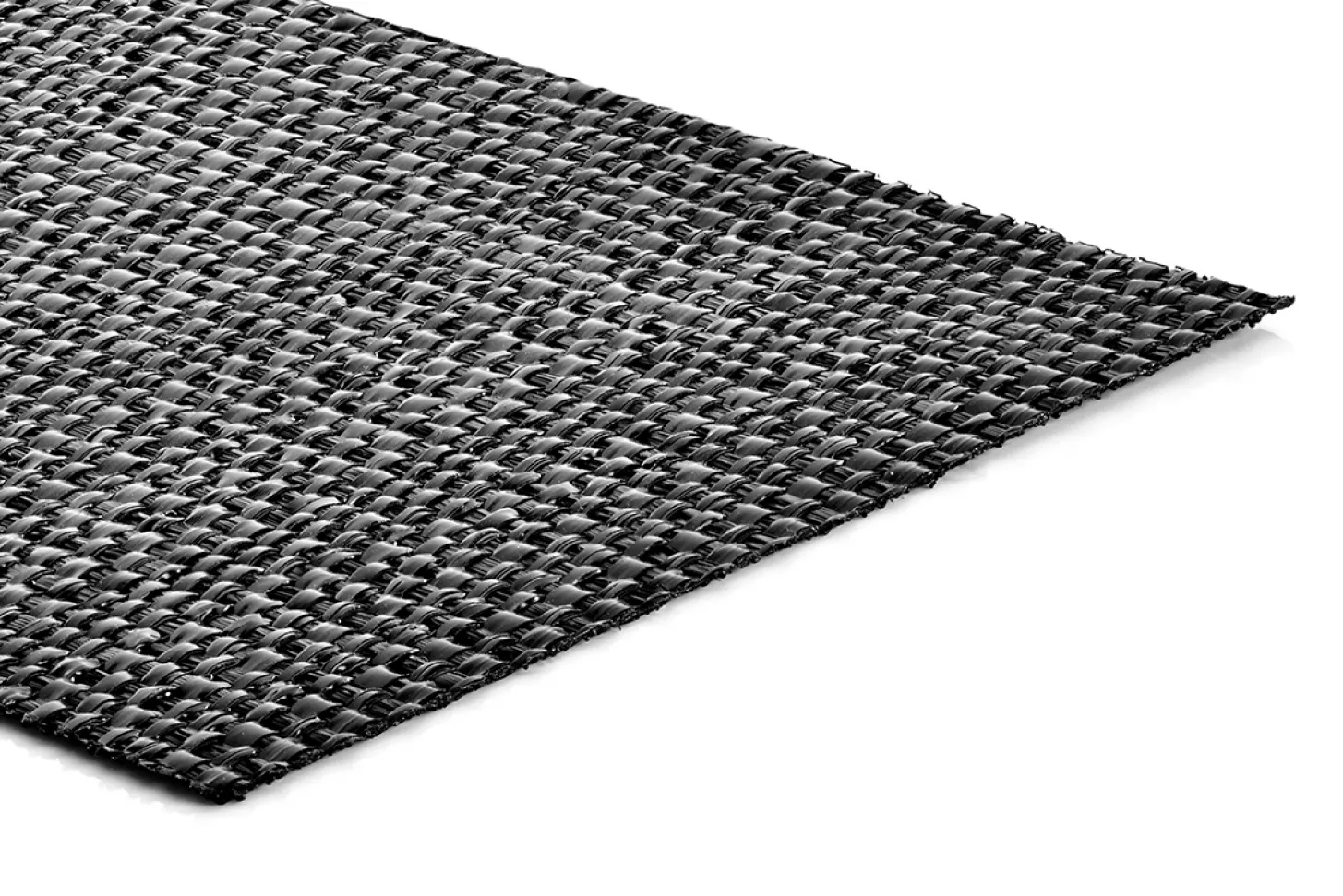

The woven tape fabric is manufactured by cutting narrow strips from a polypropylene membrane and then stretching the strips and weaving them together. The result is a uniaxial or biaxial geotextile in the longitudinal (warp) and lateral (weft) directions.

Project-specific requirements

The BEFORCE range of polypropylene woven fabrics offers a wide spectrum of special reinforcing products.

The standard BEFORCE PH 55 (PP 80) version can be used for filling with coarse-grained base-course material as well as on subgrades that deform and have a poor load-bearing capacity. It therefore exceeds the requirements for geotextile robustness class 5, as defined on pages 105-107 of the “Merkblatt über die Anwendung von Geokunststoffen im Erdbau des Straßenbaues” (Leaflet on the use of geosynthetics in earthworks for highway construction).

If there are other, special requirements in specific cases, we would be happy to determine which type of product is suitable for you.

Functions

Separation

The tightly interwoven structure of the BEFORCE Woven Geotextiles ensures effective separation of the different soil layers. This characteristic distinguishes woven geotextiles from geogrids, which only reinforce the soil and therefore require the use of an additional separating layer (such as a non-woven geotextile) in certain applications.

The standard product BEFORCE PH 55 (PP 80) exceeds the requirements for geotextile robustness class 5. This makes it a particularly robust material that provides a low-cost solution in comparison to the use of a combination of geogrids and non-woven fabrics.

Reinforcement

In order for the fabric to be able to absorb the forces acting on it, its tensile strength needs to be activated by establishing friction between the soil and the fabric (coefficient of friction). The encased soil is contained by the fabric and acts as a compression member.

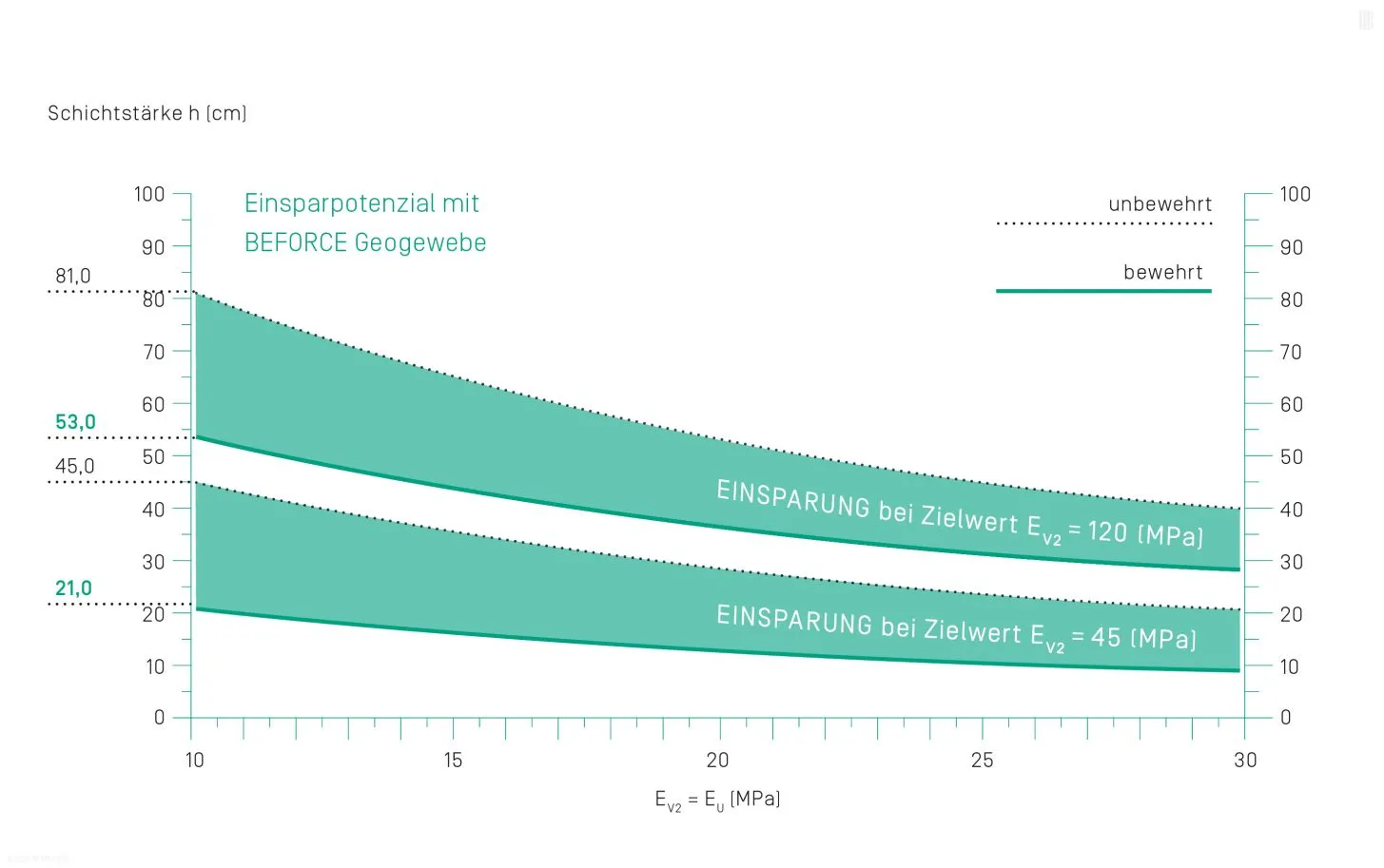

When stabilising foundation soils using BEFORCE Woven Geotextiles, the modulus of deformation, EV2, of the subgrade must first be determined in order to establish its load-bearing capacity. As a general rule, a modulus of deformation, EV2, of 45 MN/m² is required for the subgrade and 120 MN/m2 for example for the frost protection layer. In order to reduce deformation and increase the load-bearing capacity to the required level, the woven geotextile must be laid on the raw subgrade. Traffic loading causes deformation of the unbound pavement layers and this is absorbed by the BEFORCE Woven Geotextiles. In accordance with the “Merkblatt über die Anwendung von Geokunststoffen im Erdbau des Straßenbaues” (M Geok E 2016) (Leaflet on the use of geosynthetics in earthworks for highway construction), woven geotextiles are used in applications where a reinforcing and/or separating effect is required.

Technical details

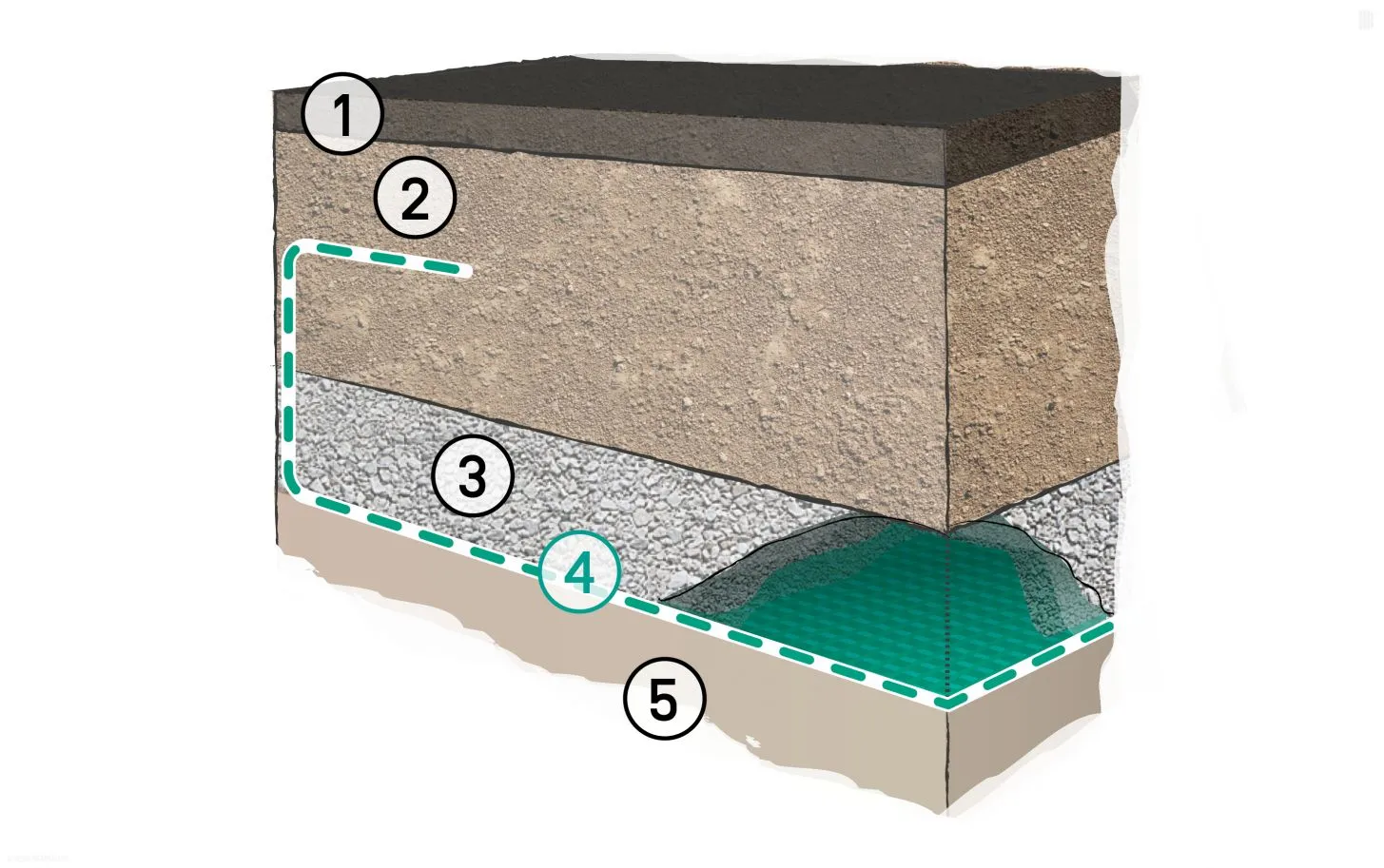

Improved foundation layer without partial soil replacement

If a reinforced base layer is constructed, there is no need for a separate analysis of the lead bearing capacity on top of the subgrade, provided that the requirement of EV2 ≥ 120 MN/m2, where EV2/EV1 ≤ 2.3, is met at the upper surface of the frost protection layer.

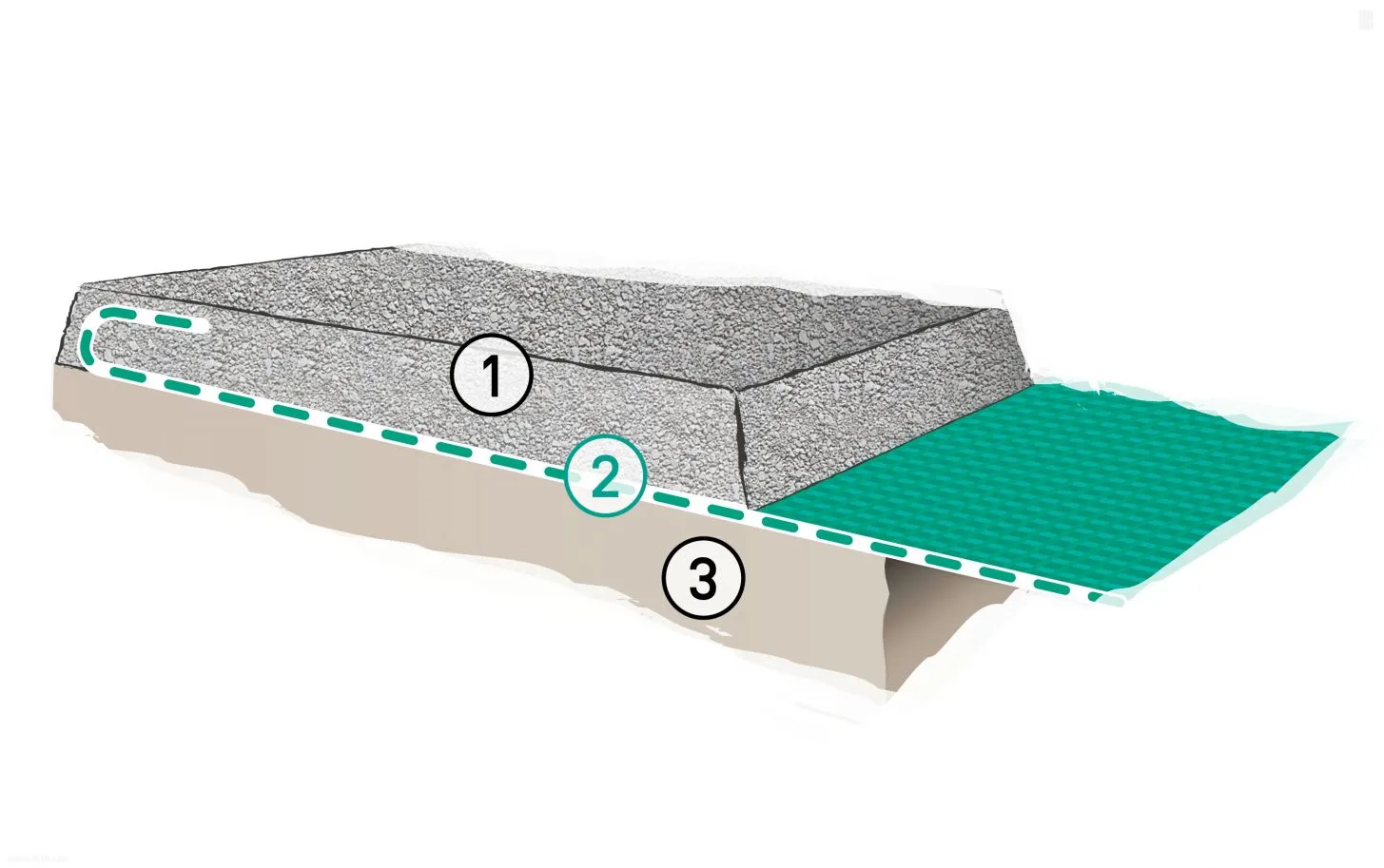

Improved foundation layer without partial soil replacement

- Bound upper construction layers

- Unbound upper construction layers

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

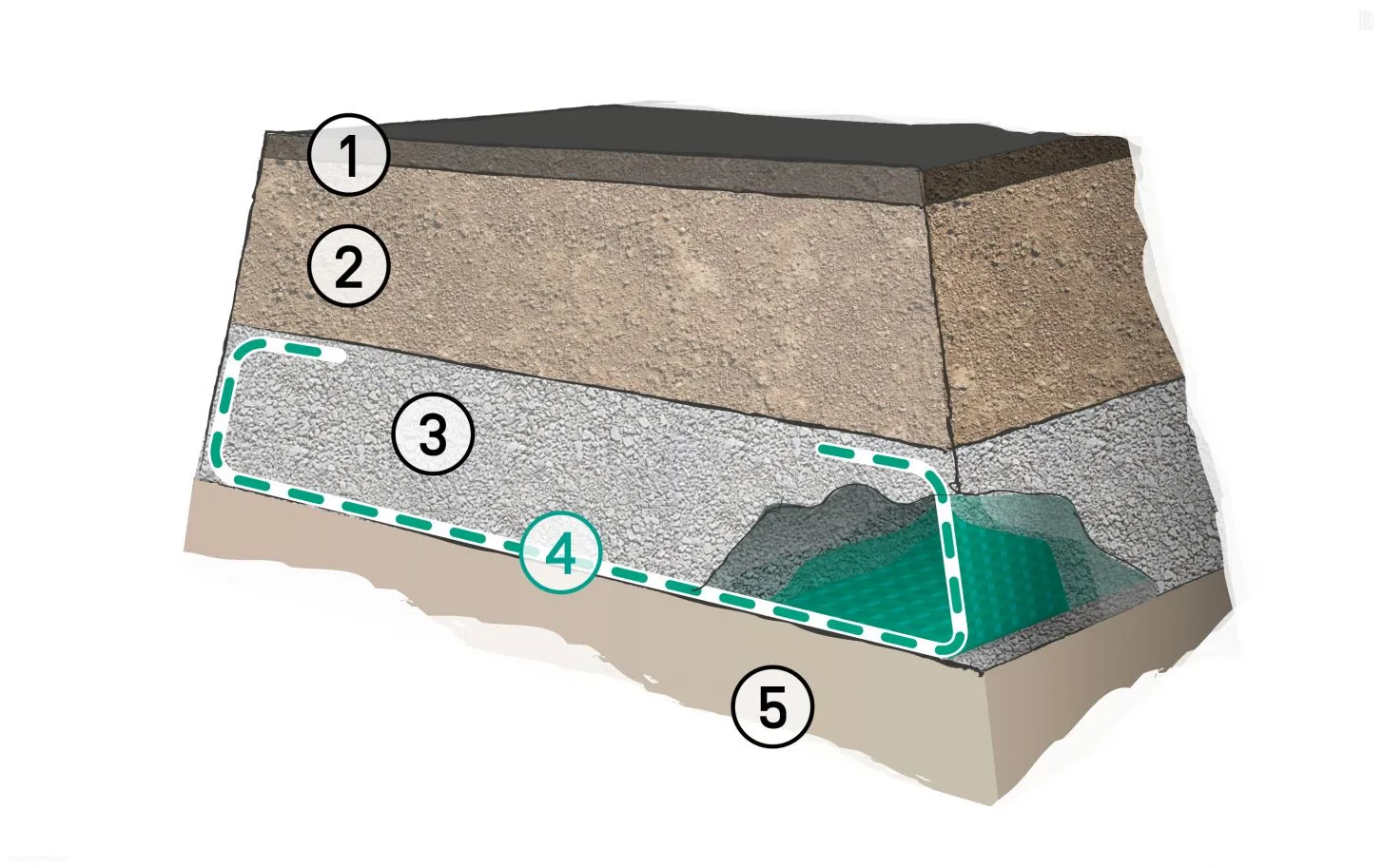

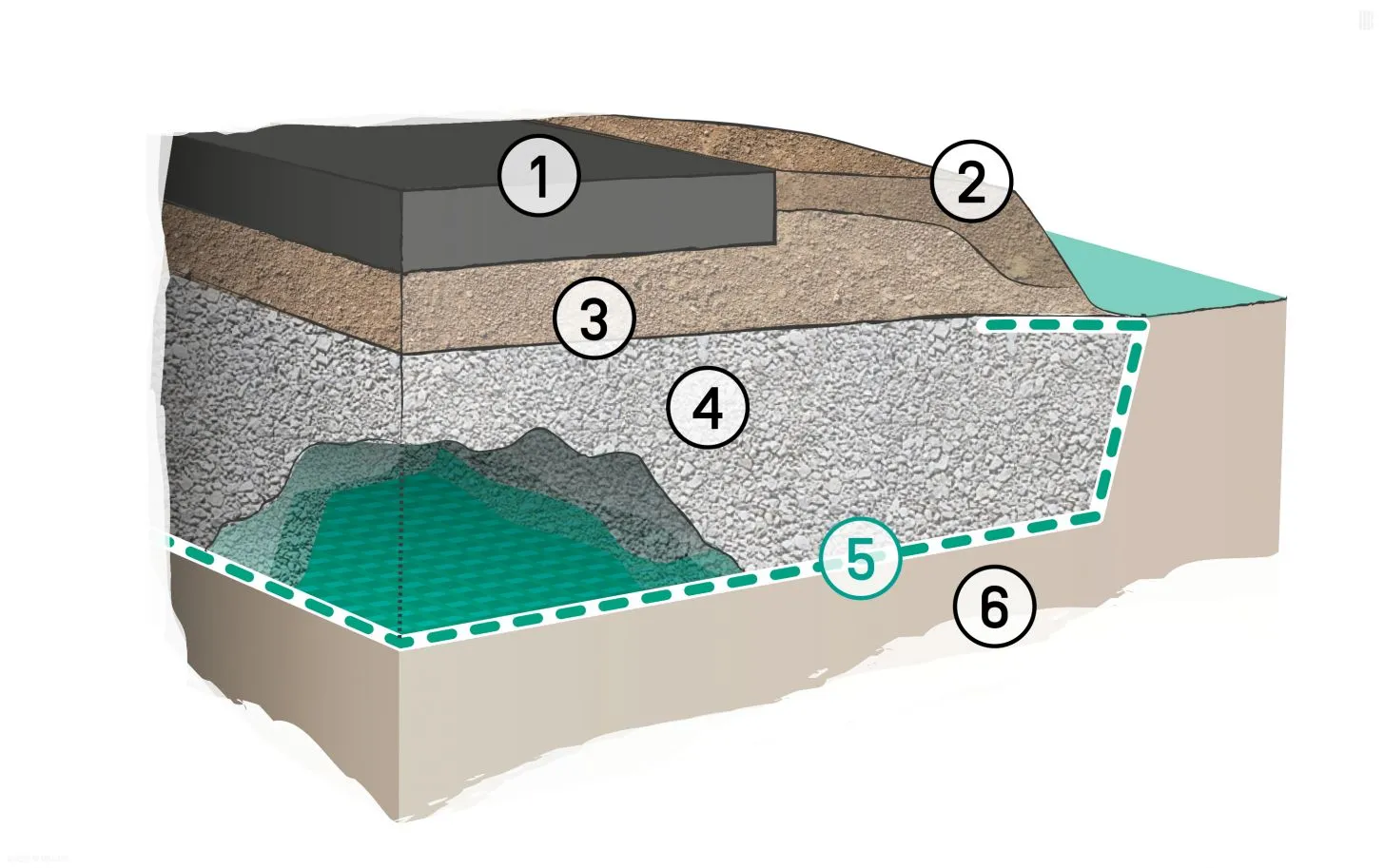

Improved base layer with partial soil replacement

If it is expected that the existing subgrade will not have the required load-bearing capacity of EV2 45 MN/m2, the subgrade or sub-base layer must be improved. One method of improvement is by replacing the existing soil and this can be minimised by using BEFORCE PH 55 (PP 80) Woven Geotextile.

Improved base layer with partial soil replacement

- Bound upper construction layers

- Unbound upper construction layers

- Partial soil replacement

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

Applications

Woven tape fabric is the preferred geotextile for surface stabilisation and for increasing load-bearing capacities in highway, traffic route and rail construction.

Particularly where substrate stabilisation for paved or unpaved traffic routes is concerned, BEFORCE woven geotextiles provide a far simpler and more cost-effective solution than conventional methods such as soil replacement or soil stabilisation using lime. Other applications include service roads, car parks, cycle paths and construction site access roads.

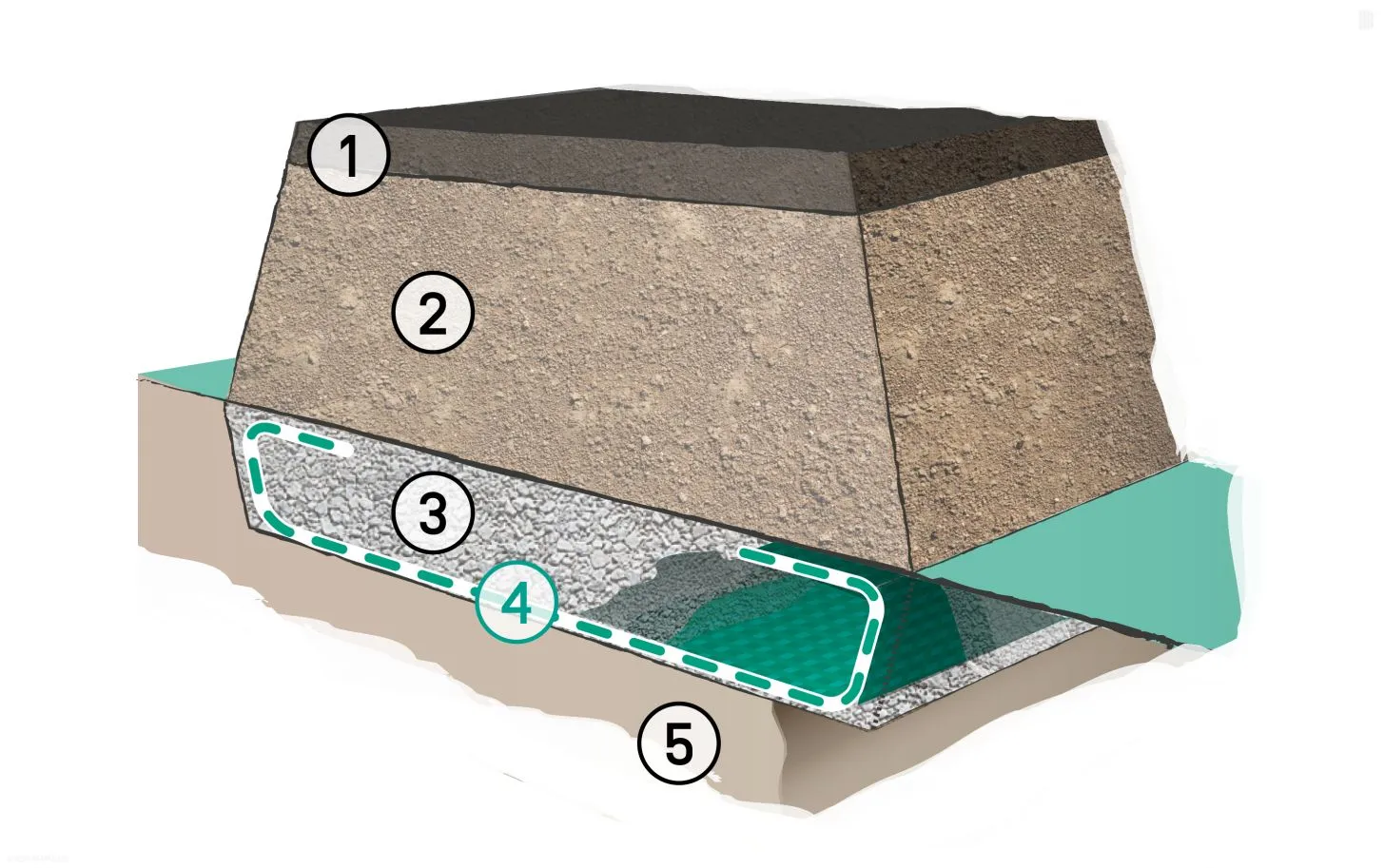

Reinforcing layer under a dam

- Bound upper construction layers

- Unbound surface layer

- Base layer

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

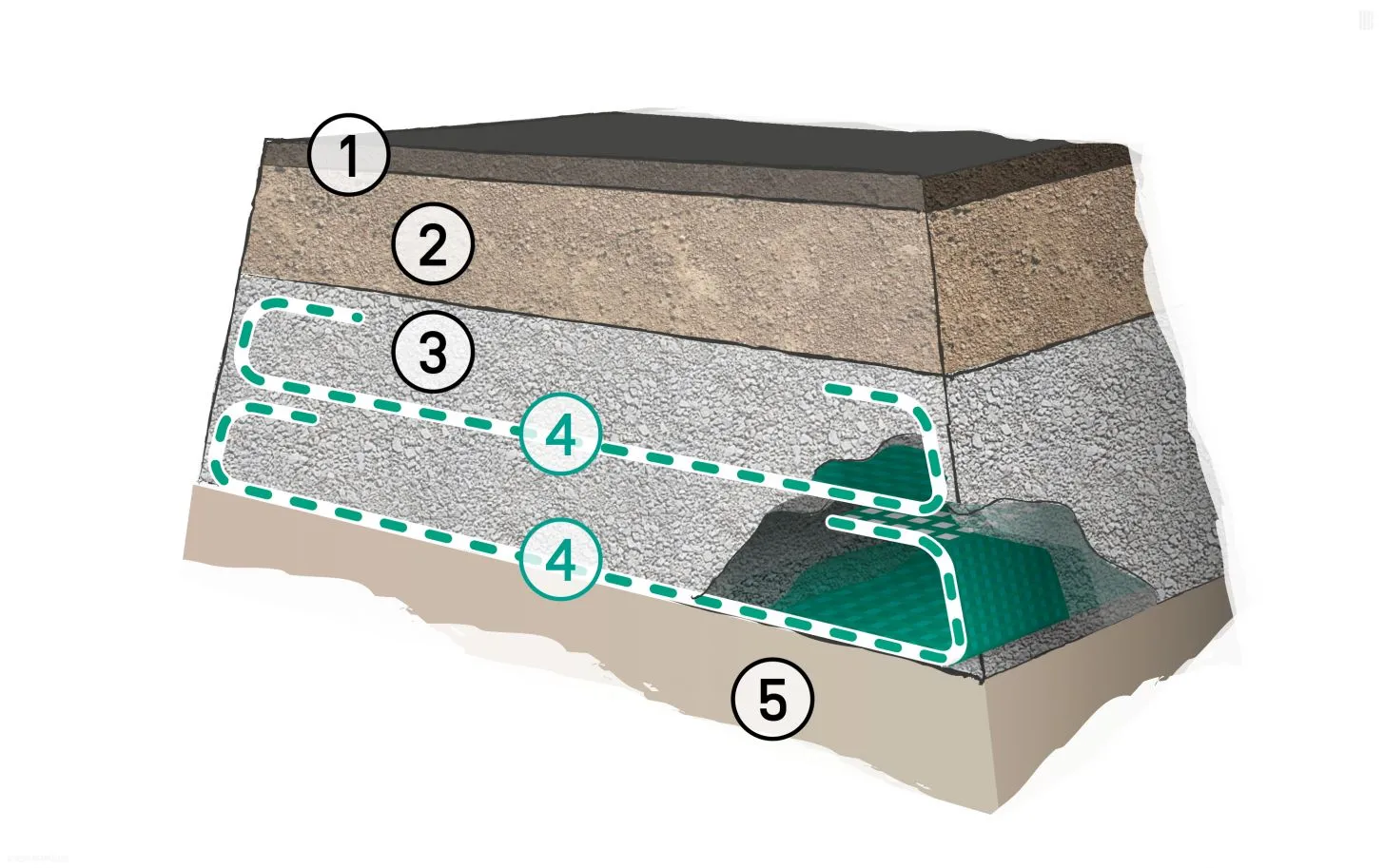

Several reinforcing layers

- Bound upper construction layers

- Unbound surface layer

- Base layer

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

Reinforced layer as soil replacement

- Bound upper construction layers

- Unbound upper construction layers

- Partial soil replacement

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

Reinforcing layer under roads with unbound surfaces (construction site access roads, service roads and access routes for site development)

- Unbound upper construction layers

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

Separating and reinforcing a layer of replaced soil to improve the load-bearing capacity of the formation layer and to support vehicular traffic during the construction phase

- Bound upper construction layers

- Verge

- Unbound sub-base

- Soil replacement using load-bearing material

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

Reinforced foundation bed as a bearing layer for pipelines

- Pipe bedding

- BEFORCE Woven Fabrics

- Subsoil with poor load-bearing capacity

Data

| Properties | PP 40 | PP 50 | PP 60 | PH 55 (PP 80) |

|---|---|---|---|---|

| Product type | Woven geotextiles | |||

| Raw material | Polypropylene (PP) | |||

| Geotextile robustness class (GRK) | 3 | 4 | 5 | 5 |

| Maximum tensile strength longitudinal / transverse | 40 kN/m | 50 kN/m | 60 kN/m | 80 kN/m |

| Areas of application | ||||

| Dike and hydraulic structures | ● | ● | ● | ● |

| Earthworks and foundations | ● | ● | ● | ● |

| Canal structures | ● | ● | ● | ● |

| Riding arenas | ○ | ● | ● | |

| Road and traffic area | ● | ● | ● | ● |

| Road construction | ● | ● | ● | ● |

Savings

The economical use of resources in road and traffic route construction no longer refers only to economic and ecological criteria in the deployment of construction equipment and personnel. Today, construction projects are subject to an overall sustainability assessment.

In a comprehensive study conducted by EAGM, the life cycle analysis of construction methods using geosynthetics revealed their ecological and economic advantages in comparison to conventional construction methods.

By using BEFORCE Woven Geotextiles, it is possible to largely or completely avoid conventional soil replacement.

The potential savings made, in comparison to soil replacement for example, can be up to 40 %, depending on the project. Added to this are the cost and time savings for excavation and disposal of the unsuitable soil and the provision, delivery and installation of replacement material. At the same time, all these savings also benefit our environment.

*The actual potential savings may vary depending on the boundary conditions of the specific project and on the frost resistance of the road pavement and the load-bearing capacity of the substrate.

POTENTIAL SAVINGS up to

%

Example: Road construction class Bk3.2, row 1, Table 1 RStO (Guidelines for the standardisation of traffic area pavements), published 2012

With BEFORCE Woven Fabrics, the costs of at least 40 cm of excavation and disposal and of the delivery and installation of replacement material are saved.

Improvement in load-bearing capacity due to BEFORCE PH 55 (PP 80) Woven Fabric

Example, based on a modulus of deformation EU = 10 MPa

Installation

- The subsoil should be as flat and even as possible in order to ensure full contact with the woven fabric across the entire surface.

- The woven geotextile must be laid flat and free of creases.

- When filling and compacting material on top of the fabric, care must be taken to prevent displacement or creasing of the fabric.

Our detailed installation and laying instructions for BEFORCE Woven Geotextiles must also be followed.

Advantages

- Separation of bearing course material from substrate

- Reinforcing effect in the foundation course

- Reduction in thickness of sub-base layer for traffic routes

- Reduced rut formation in roads with unbound surfaces

- High design reliability

- Simple to lay

- Low labour input

- Low transport costs

- Potential cost savings compared to conventional methods

Gallery

Further information about:

BEFORCE Woven Fabrics

BEFORCE Woven Fabrics

BEFORCE Woven Fabrics

Product Brochure

Further applications

Anwendungstechnik Geobaustoffe

Sebastian Schiller

MSc. Geow.

![]() +49 (0) 911 64200-29

+49 (0) 911 64200-29

![]() sebastian.schiller@beco-bermueller.de

sebastian.schiller@beco-bermueller.de

Anwendungstechnik Geobaustoffe

Fridolin Sturm

BSc. Geow.

![]() +49 (0) 911 64200-46

+49 (0) 911 64200-46

![]() fridolin.sturm@beco-bermueller.de

fridolin.sturm@beco-bermueller.de